Motivation

Given limited resources, increasing material demands, volatile supply situations, and growing climate burdens, it is essential to make value chains more sustainable and ensure supply security. The “ORCHESTER” project aims to develop digital technologies that enable sustainable and resilient material supply. Through innovative approaches, material selection is optimized, leading to a direct benefit for the industry and representing an important step towards a future-proof material supply.

Project goals

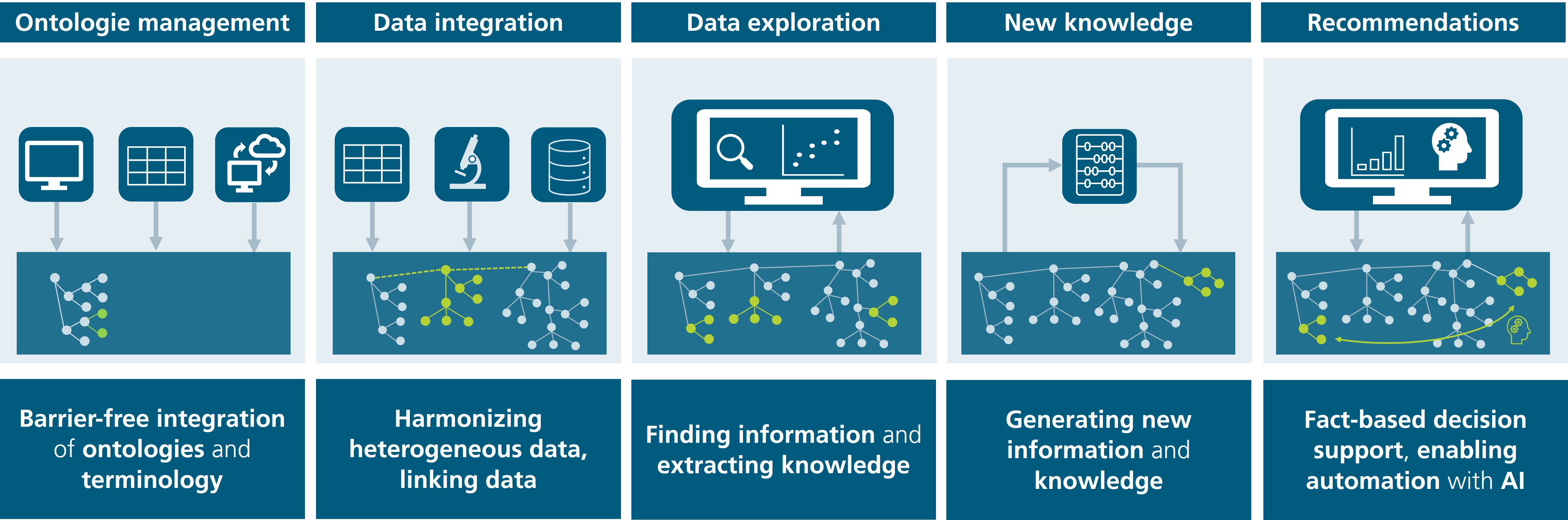

- Creation of a digital ecosystem: This knowledge base aims to improve decision-making in materials management by integrating and analyzing extensive data.

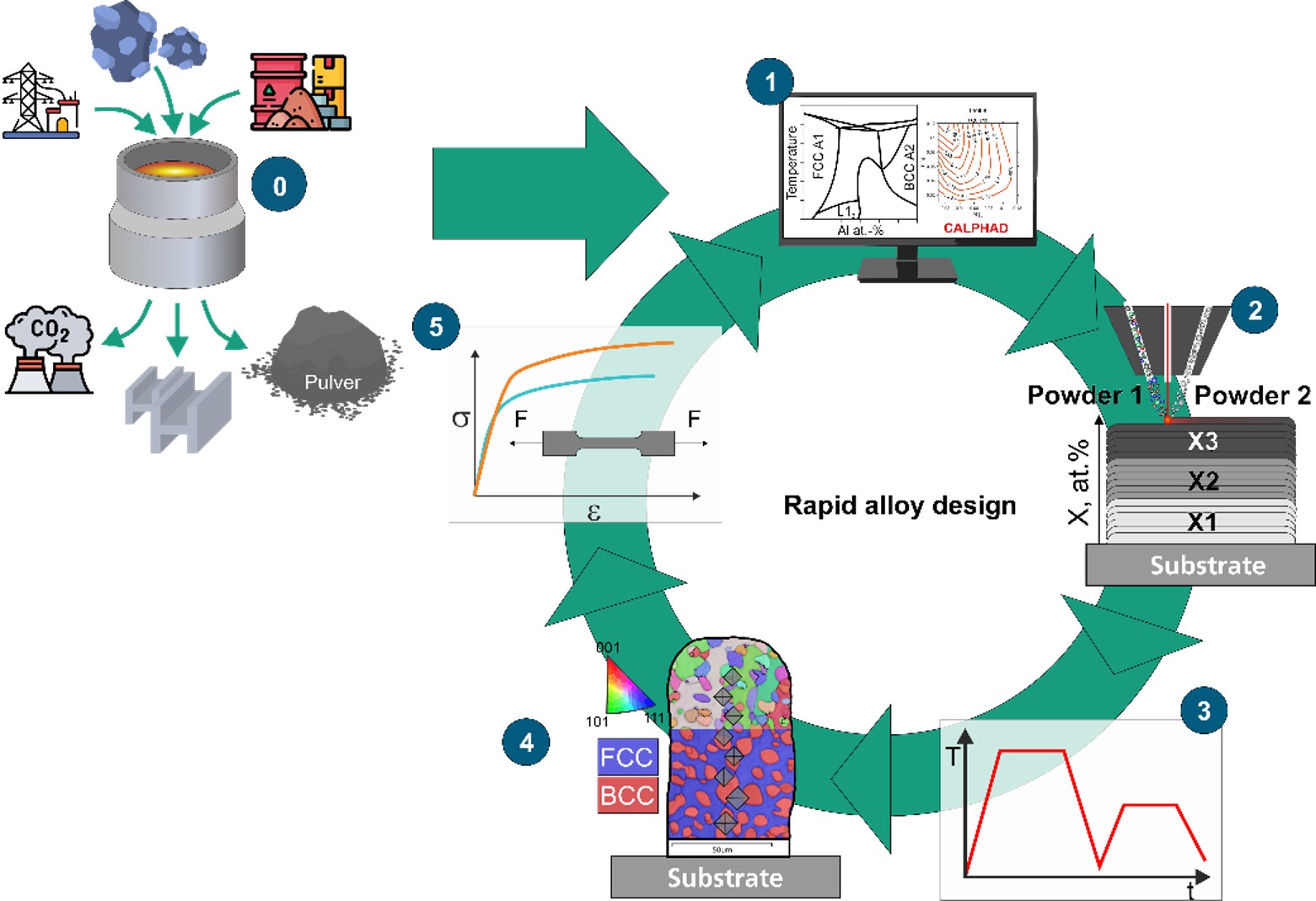

- Optimization of material development: High-throughput screening technologies enable the rapid identification of suitable materials. These technologies help efficiently develop alternative materials and alloys to increase the speed of innovation in the industry.

- Increase in recycling rate: By developing sustainable recycling strategies, such as increasing the recycling rate, raw material consumption can be reduced, while advancing the circular economy.

Fraunhofer Institute

Fraunhofer Institute